In this Article

According to the International Coffee Organization (ICO), the country’s consumption of coffee constantly increasing from 862,000 bags (60 kg bag) or 51,720 metric tons (MT) of green coffee beans (GCB) in 1999/2000 to 3,300,000 bags (60 kg bag) or 198,000 MT of GCB in 2018/2019. However, a constant decreasing trend of our country’s production was recorded by the ICO, from 622,000 bags or 37,942 MT in 1999/2000 to a decline of 206,000 bags or 12,360 MT in 2018/2019. A computed deficit was found to be of 3,094,000 bags or 185,640 MT of GCB.

The Philippine government is taking its lead to bring back the glory days of the coffee industry. A physical production target of 214,626 MT of GCB and about 14,548 hectares of expansion areas for production was aimed until 2022. Furthermore, 160 percent self-sufficiency levels and a yield per hectare of 1 MT were targeted until 2022 (2017-2022 Philippine Coffee Roadmap). However, challenges such as the lack of accredited nursery operators and mother clonal gardens, and insufficient supply of quality or certified planting materials might hinder the attainment of this goal. To be able to compete with other coffee producing countries and meet our domestic demand and to be able to achieve the targeted yield of about 0.3 to 1 MT/ha by 2022, 50,000 ha of land should be planted with quality planting materials with high yielding produce all over the country (Philippine Coffee Roadmap 2017-2022).

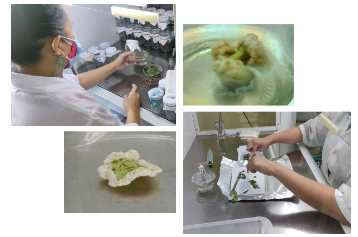

The somatic embryogenesis method of propagating coffee and the development of a high capacity growth chamber for tissue cultured coffee both aim to produce and increase the number of quality planting materials for this commodity. The positive effects of temporary immersion on micropropagation are indicated for shoot proliferation and microcuttings, microtuberization, and somatic embryogenesis.

Etienne et al. (2006) cited that bioreactors are the most promising way of scaling up micropropagation processes. The device works in large containers that enable a high degree of control on pH, aeration rate, oxygen, and other concentrations. These are compatible with the automation of micropropagation procedures and might reduce the production costs of coffee planting materials. However, commercial bioreactors, although efficient, are costly and only available abroad. Thus, this project aims to locally develop this equipment to speed up the production of quality planting materials and increase its efficiency as well as its mortality rate.

The project will develop a temporary immersion bioreactor to improve somatic embryogenesis for coffee micropropagation. The technology will address a gap in the coffee industry, which is to develop and provide quality planting materials. Quality coffee starts from quality planting materials, hence the protocol and technology that will be developed by the project can contribute to the goal of the industry/ISP roadmap for improved coffee quality.

In general, the project aims to design and develop a low-cost temporary immersion bioreactor system for the mass propagation of coffee planting materials. Specifically, it aims to:

- design a temporary immersion bioreactor system based on the design of existing commercially-available bioreactors and end-users’ preferences;

- fabricate a temporary immersion bioreactor system using low-cost and locally-available materials;

- test and evaluate the performance of the temporary immersion bioreactor system through the conduct of experiments; and

- determine the economic benefits of using the temporary immersion bioreactor system