In this Article

Pre-processing is necessary to bring quality and safe mussels to the consumers. Depuration is a process of eliminating or reducing bacterial load in mussels by transferring live harvested mussels to treated seawater using recirculating or flow-through system. These techniques allow the mussels to self-purify and expel ingested bacteria from their guts that pose risk to humans when mussels are eaten raw or partially cooked.

To address this concern, different options of depuration were explored to make the technologies available to consumers. Simple depuration protocol – Simple depuration does not need sophisticated facilities. It would only require tubs or tanks, aeration system and clean seawater. The process requires regular changing of treated seawater. This process would require more manpower and entail a higher water footprint. This technology is intended for small scale operations such as public markets and restaurants offering live bivalves to ensure food safety for its consumers. The technology is relatively crude, tedious to operate due to daily manual changing of water, and requires longer depuration time which may result in relatively higher mortality and lower meat yield.

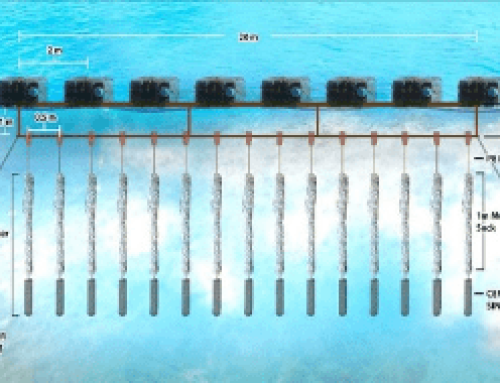

Recirculating depuration protocol – The recirculating depuration system involves the continuous flow of filtered and UV-treated seawater thus would hasten depuration process. The facility involves an efficient filtering system both for microbial and coarse contaminants, and a sterilization process to further eliminate microorganisms thus ensuring an efficient cleansing process. This depuration protocol is required by EU and USFDA prior to the placing of bivalve-like mussel in the marketplace to ensure clean and safe products. The process is recommended for industrial scale since it relatively requires higher investment.