In this Article

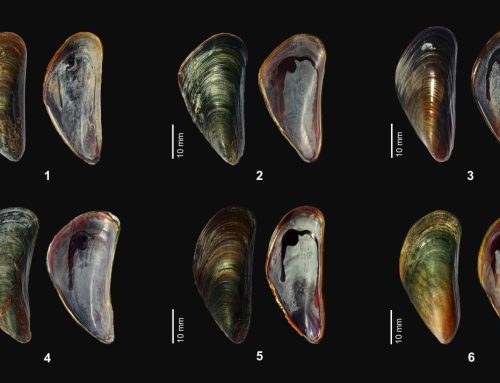

One major problem that hinders the sustainability of mussel production is the reliance of the industry on seed stock from the wild. The natural population is declining due to environmental degradation and overharvesting. Hence, there is an increased effort in developing the hatchery and nursery protocols for the green mussel to augment the natural spat supply for grow-out production.

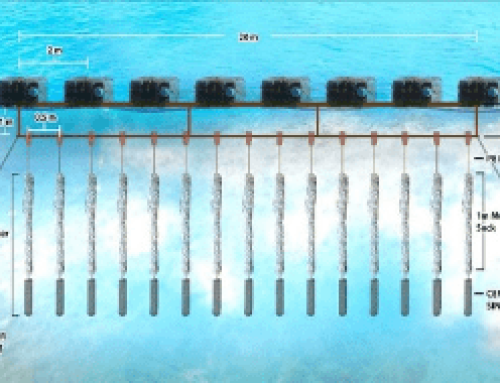

The different aspects of the green mussel hatchery are the following: hatchery site selection, culture of microalgae, broodstock maintenance, spawning, and larval and spat rearing. Hatchery facilities and equipment developed for the mussel species are patterned after shellfish hatcheries in Australia, New Zealand, and Japan. While nursery rearing is regarded as the final stage in hatchery, it holds and grows newly settled spats that have successfully settled and metamorphosed until they are ready for seeding into grow-out farms. Nurseries aim to rapidly grow 2-3 cm seeds to a size suitable for transfer and distribution to culture areas, at lower cost. With this technology, mass culture of green mussel spats is now seen as viable with developed techniques. The survival from D-hinged to early spats was now set at an average of 3.1% and survival from early spat to spat was 72%. These results were all accompanied by good and enough natural food as diets from larvae and spat, as well as enough source of clean seawater for culture and water exchange. This technology is being pilot-tested in 2022.